In Need of UPS Preventive Maintenance?

If you’re looking for a reliable technician to stop out on site to conduct a single PM “one-time” then we can support you. We understand that some UPS units do not require a maintenance contract but still need a professional checkup. Whether you are looking for a recommendation or simply budget-conscience, FGC is willing to conduct a one-time PM if necessary at any location.

One-Time PM UPS Scope

- Perform a complete visual inspection of all internal sub-assemblies, wiring harnesses, contactors, cables, and major component

- Check for proper clearance around the unit

- Perform temperature checks on all breakers, connections, and associated controls; report all high-temperature areas

- Check air filters for cleanliness; clean or replace

- Check rectifier and inverter snubber circuit board for discoloration

- Check power capacitors for swelling or leakage

- Check capacitor vent caps extruded more than 1/8 fans for proper operation

- Lubricate and check bearings for abnormal condition, where possible

- Record all meter readings and calibrate as necessary, where possible

- Measure and record phase-to-phase input, output, bypass, and battery voltages and currents, where possible

- Review alarm log/history for any irregular activity, where possible

- Verify remote status panel operation

- Measure and record harmonic-trap filter currents, where possible

- Review system performance with customer to address any questions and to schedule any repairs

- Provide inspection report, with recommendations, to customer within 7 to 10 business day

- Check the inverter and rectifier snubbers for discoloration or damaged wiring

- Check all contacts to ensure secure connections

- Verify that connections show no signs of discoloration

- Check fuses on the DC capacitor deck for continuity, as applicable

- Clean interior and exterior of unit

- With customer approval, perform operational test of the system including unit transfer and battery discharge

- Measure and calibrate, as necessary, where possible, all electronics to system specifications

- Measure and record all low-voltage power-supply levels

One-Time PM Battery Scope

Included with UPS Scope

• Measure and record each cell terminal voltage (DC and AC)

• Measure and record overall system DC voltage and current levels

• Measure and record ambient room temperature

• Measure and record temperature of all negative posts

• Measure and record AC ripple voltage and current

• Measure and record VDC and VAC of jar/cell (cell #1 + post to frame ground; frame ground to – post of last cell in string)

• Check jar and cover for signs of leakage

• Check for corrosion on terminal post and connector

• Check general appearance and cleanliness of battery room and batteries

• Review customer battery maintenance logs and add maintenance entry

• Safety check: confirm proper warning/hazard labels

• Safety check: confirm proper operational information, placards, and labeling

• Safety check: check safety equipment and supplies for proper amount and location

• Provide inspection report with recommendations to customer within 7 to 10 business days

• Torque battery to manufacturer's specification (if connection resistance measures greater than 20% of average)

• Clean and re-secure all battery terminals and jumper connections, as applicable (up to 20%)

• Clean and neutralize jar and rack/cabinet, as applicable

• Load test each jar or use equivalent device

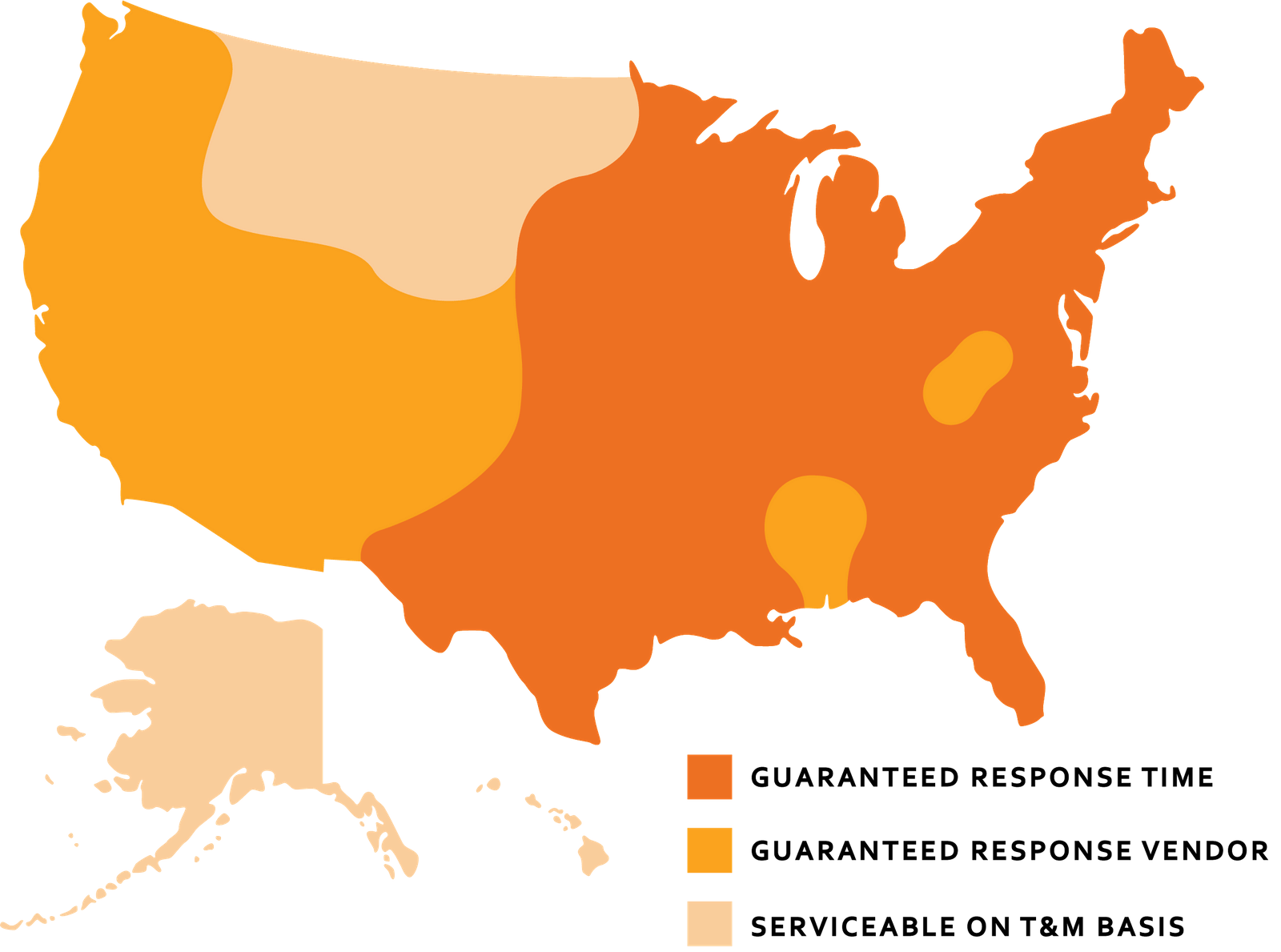

Widespread Regional Coverage

Our Wisconsin-based NOC is staffed 24 hours a day, every day. Our analysts are experienced, knowledgeable, and connected. We are moments from dispatching a quality technician to your site at any time or if you need phone tech support in the middle of the night, FGC has you covered.

What We Provide

Local Experienced Technicians

Not all technicians are created equal. Some technicians may have the intellect but lack the practical hands-on experience to PM your equipment. We believe in hiring dedicated technicians that average 20+ years of experience.

National Coverage

FGC provides UPS service in all 50 states and

some areas of Canada. Whether it is a PM

contract or Emergency service, FGC has you covered.

Fully Stocked

Batteries & Parts

As your service provider we cannot properly do our jobs without access to batteries and parts. We stock several million in parts, batteries, and replacement equipment nationally. OEM certified or vintage third party, FGC has the parts to ensure this highest UPS uptime.

In Need of One Time PM?

Our mission is to partner with your organization to ensure that your mission critical UPS experiences 100% uptime.

Created by Facility Gateway Corporation, Keys is a patented facility asset management software platform designed to keep all of your facility management operations and maintenance records in one centralized location.

Performance Tracking

Within the Facility Keys™ asset management software operating platform, KPIs (Key Performance Indicator) rate our performance as your facility management support company.

Vendor Management

We track performance criteria such as the number of PMs (preventive maintenance) scheduled/re-scheduled per month and emergency call performance and resolution.

Asset Management

Facility Keys™ asset management software saves time and eliminates paper chasing by keeping a complete list of your facility management reports and documents at your fingertips.

Site Information

View a snapshot of all sites in one location and the number of assets per site, along with details like location, manufacture, upcoming schedule, and data center performance.

Procurement Management

View all quotes, purchase orders, and invoices related to each site and specific asset. This feature can possibly help lower your current price of procurement by streamlining your strategy.

Learn more about

Facility Keys™

What Our Clients Have to Say

Work With Us Today.

We have emergency service available 24/7/365 nationally. Call our U.S. based NOC at 866-432-1711. Let us be your partner for uninterruptible power supply services.